Polyaspartate synthesis (rootGrow)

1. Polyaspartate synthesis (rootGrow)

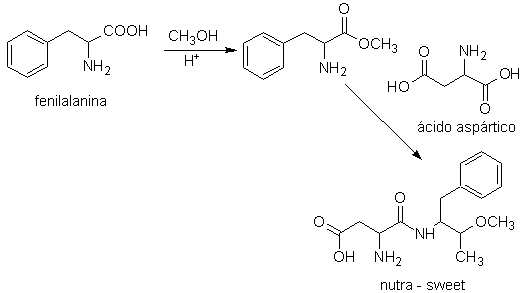

It is claimed that the rootGROW formula is related to that of nutra-sweet (aspartame), a powerful sweetener, which is being withdrawn or has already been withdrawn from the market, due to its harmful effects on people's health.

Nutra-sweet can be synthesized from phenylalanine, according to the following scheme:

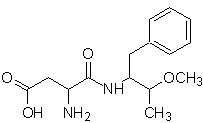

nutra sweet

In turn, the aspartic acid, the fundamental base, to obtain the rootGrow, which can be dextrorotatory (D) or levorotatory (L), is prepared according to the following synthesis schemes:

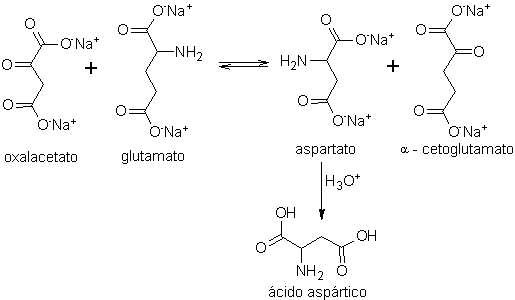

Scheme A: (transamination process)

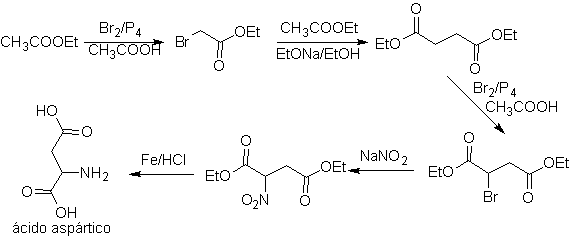

Scheme B. (From nitroderivatives and the use of the HV Z reaction)

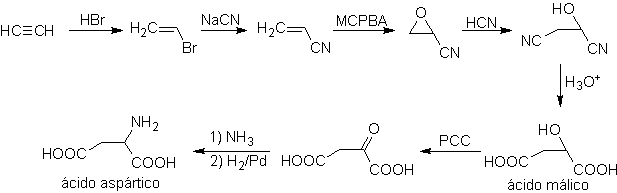

Scheme C. (via malic acid formation)

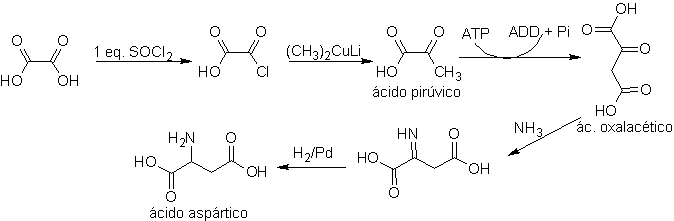

Scheme D (From oxalic acid)

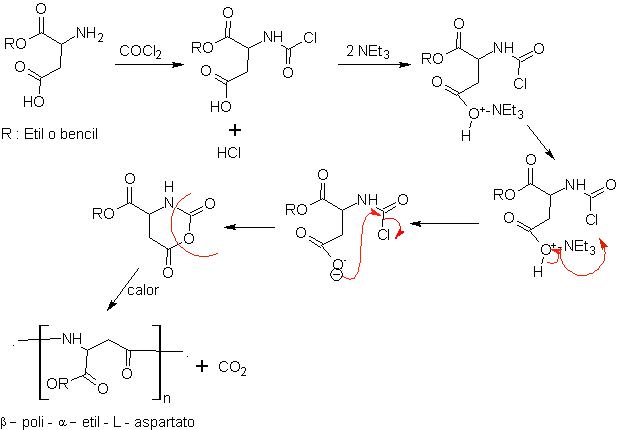

Synthesis of polyaspartate (rootGROW)

RootGROW ( poly-aspartate ), a condensation polymer can be synthesized with good yields by biosynthetic and chemical procedures, starting from L-aspartic acid, an aspect that results in the affordable price of the product.

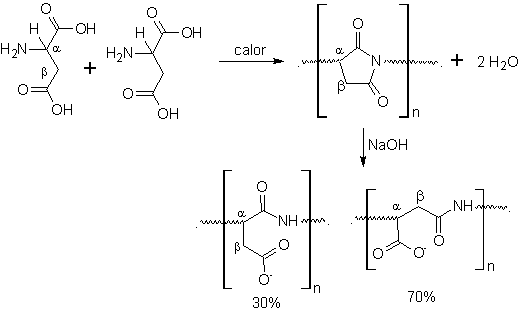

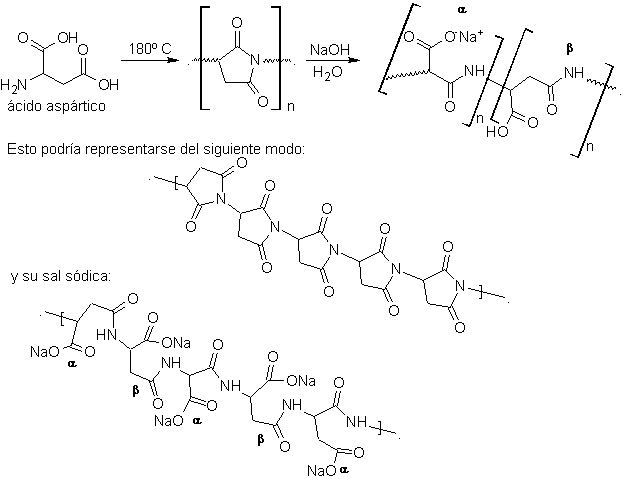

In reality, polyaspartate is a polysuccinimide, a unit that is repeated many times in the polymer and to use it, it is normally prepared with NaOH, which opens the succinimide ring at two different places in relation to the amide. The alpha and beta bonds are hydrolyzed resulting in a sodium salt of the poly(aspartate) copolymer with 30% alpha-linked and 70% beta-linked compounds.

Biosynthesis procedures:

L-diethyl-aspartate is polymerized by a bacterial protease from Bacillus subtilis (BS) in organic solvents at a temperature between 30 and 50ºC, to obtain poly(ethyl-L-aspartate) with a molecular mass of M=3700 and a maximum polymerization yield of 85%.

Polymerization improves if working at 40ºC, using 30% BS of the protease containing 4.5% water by volume, in acetonitrile as solvent for two days. Poly(ethyl-L-aspartate) is readily depolymerized by the enzyme into the L-aspartate oligomer and monomer in aqueous acetonitrile.

In contrast, poly(sodium aspartate) prepared by saponification of poly(ethyl-L-aspartate) is easily biodegradable by activated sludge, obtained from municipal wastewater treatment plants.

Chemical procedures:

In reality, these procedures are known as thermal procedures, since relatively high temperatures are used, to achieve the transformations and formation of the intermediate precursor molecules, the following alternative synthesis schemes for rootGROW are proposed:

Scheme 1.

Scheme 2: